admin1

November 5, 2025

Everything to Know to Be Sure You Have the Right Lug Nuts

To be sure you have the right lug nuts, you must match three critical specifications to your vehicle and wheels: Seat Type, Thread Size, and Length. The most important of these must be lug nuts with the correct seat. A mismatch is extremely dangerous and can cause a wheel to loosen or detach. This guide helps you select the right wheel lug nuts, ensuring they will be lug nuts that provide a secure fit.

Did You Know? 😲 An estimated 50,000 tire separations occur each year in the U.S., often due to incorrect wheel hardware. A Canadian study found that 83% of wheel separations happened shortly after vehicle servicing.

Why You Must Be Sure You Have the Right Lug Nuts

You might think of them as simple hardware, but wheel lug nuts are one of the most important safety components on your vehicle. They are the only things that clamp your wheels to the car, bearing immense forces like acceleration, braking, and cornering. Choosing the correct ones is not just about a good fit; it is about preventing a catastrophic failure on the road.

The Critical Role of Wheel Lug Nuts in Safety

The consequences of failing to secure your wheels are severe. In one tragic case, a wheel detached from a tractor-trailer because the driver failed to secure the lug nuts, leading to a fatal accident. In another incident, a driver suffered devastating facial injuries when a loose lug nut from another truck flew through her windshield at 60 mph. These must be lug nuts that are properly installed. Legal cases also highlight the danger; one man received a $7.7 million settlement after a loose tire from a truck struck his vehicle, causing a traumatic brain injury. These events show why your wheel lug nuts demand your full attention.

What Happens with an Incorrect Fit?

Using the wrong wheel lug nuts creates a dangerous situation and causes expensive damage. An incorrect fit prevents the nut from properly clamping the wheel to the hub. This leads to several problems:

- Vibrations: You will feel a shimmy or vibration while driving, which gets worse at higher speeds.

- Damaged Parts: Incorrectly fitted wheel lug nuts can stretch or round the threads on your wheel studs. This can also damage the threads inside the wheel hub, a much more costly repair.

- Wheel Loosening: The constant vibration will eventually cause the lug nuts to back off and loosen completely.

Safety Alert! ⚠️ The most dangerous mismatch is an incorrect seat type. For example, using a conical seat nut on a wheel that requires a ball seat creates a tiny contact point. This point cannot handle the vehicle’s load, and the wheel will inevitably loosen. Your wheel hardware must be lug nuts that match perfectly. They must also be lug nuts that are torqued correctly.

Step 1: Identify the Correct Lug Nut Seat Type

Choosing the correct lug nut seat is the most important step for wheel safety. A mismatch here is the number one cause of wheels loosening. You must ensure the seat of your nut perfectly matches the seat in your wheel’s lug hole.

What is a Lug Nut Seat?

The lug nut seat is the surface of the nut that makes direct contact with the wheel. Think of it as a matching puzzle piece. The shape of the nut’s bottom must fit perfectly into the machined hole on your wheel. This perfect fit creates the maximum contact area. A large contact area distributes the clamping force evenly. This prevents the lug nuts from vibrating loose and keeps your wheel securely attached to your vehicle.

Pro Tip 🧐 Never assume your new aftermarket wheels use the same seat type as your factory wheels. Always check the wheel’s specifications or inspect the lug hole to confirm the required seat type before buying a new set of lug nuts.

Conical Seat (Acorn/Tapered)

The conical seat is the most common type you will find. It has a straight, cone-shaped bottom, which is why people often call it an “acorn” or “tapered” nut. This design self-centers the wheel as you tighten it.

You will find conical seats on a wide variety of vehicles. They are especially common on factory wheels from many domestic American car brands.

- Most domestic brands, like Ford and Chevrolet, have a long history of using conical seats.

- Many aftermarket wheel companies also design their wheels for this popular seat type.

Ball Seat (Radius/Spherical)

A ball seat lug nut has a distinct, rounded or spherical bottom. You can easily see the difference when you compare it to a cone-shaped conical nut. This “radius” shape requires a matching rounded seat in the wheel hole. You cannot use a conical nut on a wheel made for a ball seat, or vice versa. The small point of contact will fail under pressure.

This seat type is standard for several major European and Japanese automakers. If you drive one of these brands, you likely need the correct lug nut with a ball seat for your factory wheels.

- Honda

- Acura

- Volkswagen (VW)

- Audi

- Mercedes-Benz

- Porsche

Critical Safety Warning! 🛑 Using a conical nut on a ball seat wheel (or the other way around) creates a tiny, unsafe contact point. This point cannot handle the forces of driving. The nut will dig into the wheel, damage it, and eventually work itself loose, which could cause the wheel to fall off.

Mag Seat (Shank with Washer)

You can spot a mag seat lug nut easily. It looks very different from the others. Mag seat lug nuts have an extended thread design with a long, straight shank that sticks out. They also include a separate flat washer. This design allows the washer to sit flush with a flat surface around the wheel’s lug hole.

Think of the shank as a peg that fits perfectly into the hole on your wheel. This shank centers the wheel precisely on the hub. The flat washer then provides all the clamping force, pressing the wheel securely against the vehicle’s hub. The shank itself does not create the clamping pressure; its main job is alignment.

You will often find mag seat lug nuts on specific factory wheels, especially from Japanese manufacturers. If you own one of the following vehicles with its original wheels, you likely need this type of nut:

- Toyota models like the Tundra and Sequoia

- Lexus models like the LX, LS, and LC

Important Note! 📝 The washer on a mag seat lug nut is not optional. It is a critical part of the system. Never use a conical or ball seat nut on a wheel designed for a mag seat. The tapered nut will have nothing to grab onto, and it will be impossible to secure the wheel safely. This will cause severe wheel damage and lead to the wheel loosening while you drive.

Step 2: Determine Your Vehicle’s Thread Size

After confirming your seat type, you must find the correct thread size for your wheel bolts. The thread size is a specific measurement that ensures the lug nuts will screw onto your vehicle’s wheel studs properly. Using the wrong size can strip the threads on both the nut and the stud, making it impossible to secure your wheel.

How to Find Your Thread Size

You have a few simple ways to find the correct lug nut size for your car.

- Check Your Owner’s Manual: Your vehicle’s manual often lists the specification for its wheel bolts in the maintenance or tire section.

- Use an Online Database: Many websites offer comprehensive fitment data. You can search by your vehicle’s make, year, and model to find the exact thread size, along with other details like center bore and offset values.

- Match an Existing Nut: You can take one of your current lug nuts to an auto parts store. They have tools to measure it and find a perfect match.

Understanding Diameter and Pitch

A thread size specification has two numbers. For example, you might see M12x1.5 or 1/2"-20.

The first number is the diameter of the stud. This is the outer, crest-to-crest distance of the threads. The second number is the thread pitch. This measures the distance between threads.

Metric vs. SAE/Imperial 📏 For metric wheel bolts (like

M12x1.5), the pitch is the distance in millimeters between each thread. So, 1.5 means the threads are 1.5mm apart. For SAE wheel bolts (like1/2"-20), the pitch is the number of threads per inch (TPI). So, 20 means there are 20 threads in one inch.

Common Metric and SAE Sizes

Most modern cars use metric wheel bolts, while many older domestic trucks and cars use SAE sizes. Knowing which system your car uses helps you narrow down the correct lug nut size. Below are some common examples.

| Lug Nut Size | Common Car Brands/Models |

|---|---|

| M12 x 1.25 | Nissan, Subaru, Infiniti |

| M12 x 1.5 | Honda, Acura, Toyota, Lexus, BMW |

| M14 x 1.5 | Chevrolet, GMC, Cadillac, VW, Audi |

Common SAE Sizes

| Lug Nut Size | Associated Vehicles/Notes |

|---|---|

| 1/2″-20 | Many Jeep, Ford, and Dodge/Chrysler/Ram models |

| 9/16″-18 | Heavy-duty Ford, Dodge, and GM trucks |

| 7/16″-20 | Some older GM and Ford passenger cars |

Step 3: Choose the Proper Lug Nut Length

Once you have the right seat and thread size, you must select the correct lug nut length. The length is crucial for ensuring the nut can grip the wheel stud securely. A nut that is too short will not engage enough threads, creating a major safety hazard.

The Rule for Safe Thread Engagement

You must achieve sufficient thread engagement for a safe installation. Insufficient engagement can lead to catastrophic failure. For example, using an impact gun on a barely-started nut can easily strip and destroy both the stud and the nut. In the worst cases, this leads to “wheel off” accidents. One such incident, where a wheel detached and caused a fatality, resulted in a settlement of $1,875,000, highlighting the severe consequences.

To avoid this, you can follow a simple rule for proper engagement.

The Diameter Rule 📏 The length of the stud that goes into the nut should be at least equal to the diameter of the stud itself. For example, if your vehicle has M12x1.5 studs, you need at least 12 mm of thread engagement.

This rule ensures the nut has enough grip to handle the forces of driving without stripping or loosening.

Open-End vs. Closed-End Lug Nuts

You will choose between two main styles based on your vehicle’s needs: open-end and closed-end.

Closed-End Lug Nuts: These are the most common style. They have a capped end that protects your wheel studs from dirt, water, and rust. Many people prefer them for their clean, finished appearance. However, you must be sure they are deep enough. If the stud hits the inside of the cap before the wheel is tight, you cannot secure your wheel.

Open-End Lug Nuts: These have a hole that runs all the way through. You must use open-end lug nuts if your vehicle has extended wheel studs that would pass through a closed-end nut. This style is often required for racing applications. The main drawback is that they can allow debris and water to collect on the threads, which may make them difficult to remove later.

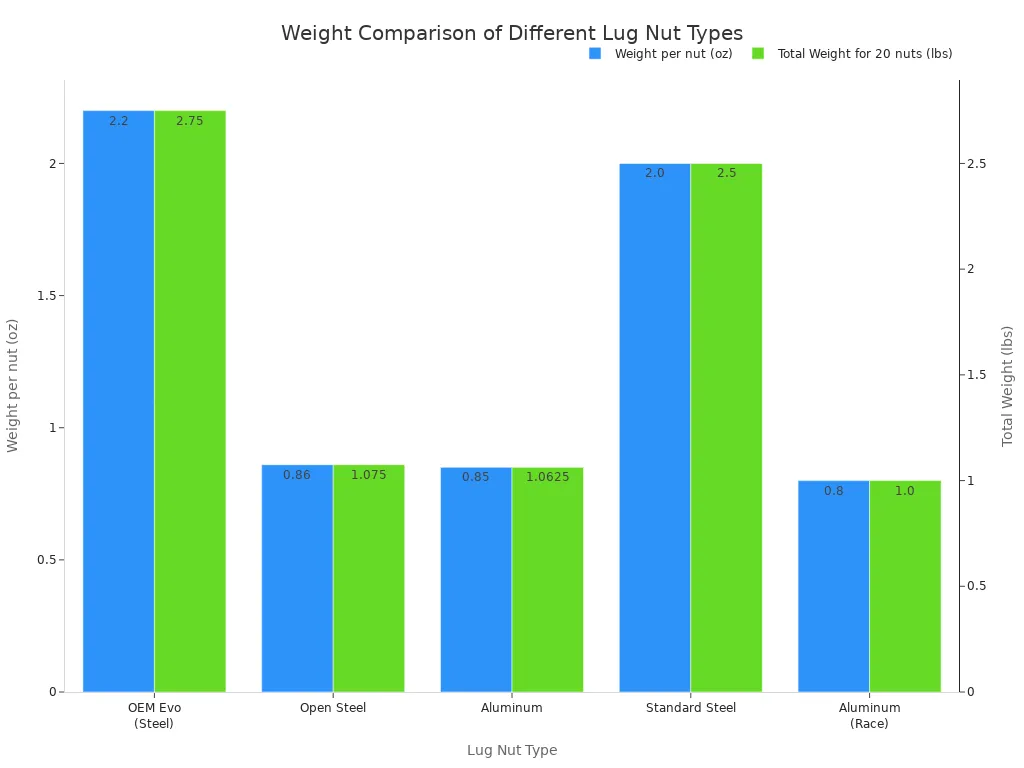

Step 4: Selecting Material for Your Custom Wheel Lug Nuts

Your material selection for custom wheel lug nuts impacts strength, weight, and appearance. The materials used for wheel lug nuts range from standard steel to lightweight alloys. You must choose a material that fits your specific needs, whether for daily driving, racing, or show. When you choose lug nuts for aftermarket wheels, the material is a key decision.

Steel: The Industry Standard

Steel is the most common material for wheel lug nuts for good reason. It offers excellent strength and durability at an affordable price. Most factory and many aftermarket wheel lug nuts are made from steel because it can handle the immense forces of daily driving without issue. The high tensile strength of steel ensures a secure clamp and long-term reliability. This durability makes steel a safe and practical choice for most drivers looking for dependable custom wheel lug nuts.

Strength by the Numbers 💪 To understand the strength differences, look at the tensile strength, which measures how much force a material can take before breaking.

Material Tensile Strength (PSI) Grade 8 Steel 150,000 Aerospace-grade Titanium 130,000 12.9 Steel Bolts (Ultimate) 176,946

Titanium & Aluminum: For Racing and Show Cars

If you want to reduce weight or enhance your vehicle’s look, you can explore titanium and aluminum custom wheel lug nuts. When you compare steel lug nuts with aluminum lug nuts, the biggest difference is weight. Aluminum custom wheel lug nuts are significantly lighter, which reduces unsprung mass and can slightly improve handling for racing.

Titanium offers a unique balance. It is stronger than aluminum and has a better strength-to-weight ratio than steel. Titanium custom wheel lug nuts also have excellent durability for repeated tightening, making them a top choice for serious racers who need lug nuts for aftermarket rims. These premium custom wheel lug nuts are perfect for performance applications.

Understanding Finishes: Chrome vs. PVD

The finish on your custom wheel lug nuts protects them from corrosion and defines their look.

- Chrome: This is the classic, mirror-like finish. It provides good protection against rust but can chip or peel over time if not cared for properly.

- PVD (Physical Vapor Deposition): This is a modern finishing process that bonds the coating to the metal at a molecular level. PVD finishes are much thinner than chrome but offer superior durability against scratches, chips, and harsh weather. These are excellent custom wheel lug nuts for long-lasting color and protection, especially for lug nuts for aftermarket rims.

Step 5: The Final Check for All Wheel Hardware

You have selected the right parts. Now you must install them correctly. This final check ensures your wheel hardware provides maximum safety on the road. Proper installation is just as important as choosing the right components.

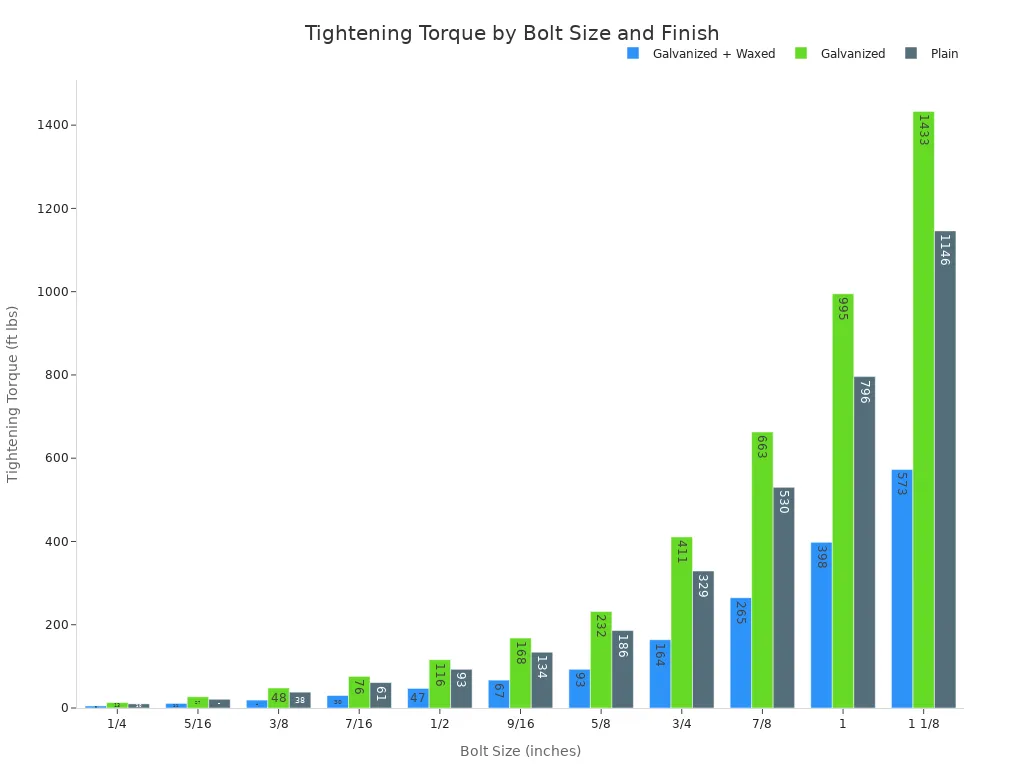

Why You Must Use a Torque Wrench

You must use a torque wrench to tighten your wheel lug nuts. This tool measures the rotational force (torque) you apply, ensuring each nut is perfectly tightened. Guessing the tightness with a standard lug wrench is extremely dangerous. Both over-tightening and under-tightening can lead to failure of your wheel hardware.

Warning! ⚠️ Over-tightening is a common mistake that causes serious damage. It can:

- Stretch the threads on your wheel studs, making them weak and likely to break.

- Cause the wheel studs to snap off completely.

- Damage the lug nuts themselves, preventing a secure fit.

Under-tightening is also unsafe, as it allows the wheel to loosen while you drive. A torque wrench is the only tool that guarantees you apply the exact force needed for your wheel hardware.

Finding Your Vehicle’s Torque Specs

Every car has a specific torque value recommended by the manufacturer. You must use this exact specification. The best places to find this information are:

- Your vehicle’s owner’s manual.

- The official factory service manual.

While general charts exist, you should always prioritize the value listed for your specific car. The correct torque ensures your wheel hardware clamps the wheel with the right amount of pressure.

The Star Pattern Tightening Sequence

You must tighten your wheel hardware in a specific order. This is called the star pattern (or cross pattern). This sequence applies pressure evenly across the hub, seating the wheel perfectly flat. If you tighten the nuts in a circle, the wheel can tilt slightly, creating a dangerous wobble.

For a five-lug wheel, you tighten one nut, then skip one and tighten the next, moving in a star shape until all are snug. After snugging them down, you will go around again in the same star pattern to apply the final torque value. This method is critical for all wheel hardware installations.

The Critical 50-Mile Re-Torque

Your work is not finished just because the wheels are on the car. The final, most important safety check is the 50-mile re-torque. Industry best practices confirm this step is not optional. It is a critical procedure to ensure your wheel hardware remains secure after being exposed to real-world driving conditions. This final check accounts for the natural settling of metal components and is your best defense against a wheel loosening over time.

After you drive for about 50 to 100 miles, several factors can cause your lug nuts to lose their initial torque value. The new wheel hardware needs this short period to settle properly.

- The full weight of your vehicle presses down on the wheels.

- Rotational forces from driving can cause tiny shifts.

- Your wheels go through cycles of warming up and cooling down.

- Bumps and potholes in the road can nudge components.

- Small bits of dirt, rust, or sand between surfaces can create a ‘false torque‘, which disappears as the parts settle, leaving the nut loose.

Peace of Mind in 5 Minutes ⏱️ To perform the re-torque, wait for your wheels to cool down completely. Then, using your torque wrench, check each lug nut again in the star pattern. You may find that some nuts turn slightly before clicking. This small adjustment is what locks in your safety for the long haul, confirming your wheel hardware is perfectly seated. Skipping this step means you are driving with potentially loose wheel hardware, which completely undermines all your previous hard work. This simple re-check ensures your wheel hardware provides lasting security.

You have successfully chosen the right lug nuts if you can answer “Yes” to this final safety checklist.

- Seat Type Matched? (e.g., Conical nuts for conical wheel seats) ✅

- Thread Size Matched? (e.g., M12x1.5 nuts for M12x1.5 studs) ✅

- Sufficient Length? (Engagement is at least the stud’s diameter) ✅

- Torqued to Spec? (Using a torque wrench and star pattern) ✅

- Re-Torqued After 50 Miles? (To account for settling) ✅

A “yes” to all five confirms a safe installation for your vehicle. These checks give you peace of mind that your lug nuts are secure.

FAQ

Can I reuse my old lug nuts on new wheels?

You should avoid reusing old lug nuts. They can stretch and wear out over time, which reduces their clamping force. For maximum safety, you should always install new lug nuts when you get new wheels to ensure a perfect and secure fit.

Do I really need a torque wrench to install lug nuts?

Yes, you must use a torque wrench. An impact gun or a standard wrench can easily over-tighten your lug nuts. This can stretch and break your wheel studs. A torque wrench ensures you apply the exact, safe clamping force your vehicle manufacturer specifies.

Why can’t I put oil or grease on my wheel studs?

You must never lubricate your wheel studs. Oil creates a false torque reading, causing you to over-tighten the nuts. This dangerous practice can lead to stretched threads, damaged wheels, and broken studs, which could cause a wheel to detach while you are driving.

Do aftermarket wheels require special lug nuts?

Yes, they often do. Your new aftermarket wheels may have a different seat type than your factory wheels. For example, you might need conical seat nuts for your new wheels, while your old ones used a ball seat. Always match the lug nut seat to the wheel.