admin1

October 12, 2025

Are Your Car Tire Nuts Actually Holding You Back?

Your factory-installed lug nuts may be holding your car back. These standard car tire nuts often add unnecessary weight to your wheels. This can limit your vehicle’s handling performance. The material strength of a stock lug also might not be enough for high-stress driving. Your expensive aftermarket wheels deserve better than a basic lug. Upgrading your tire hardware is a small change. It delivers big improvements in tire strength, weight reduction, and overall style.

The Performance Gains of Upgrading Your Car Tire Nuts

Upgrading your car tire nuts offers tangible benefits beyond just looks. You can unlock real performance gains by choosing the right aftermarket lug. These small parts play a big role in how your car feels and responds on the road.

Reducing Unsprung Weight for Better Handling

Every pound matters, especially on your wheels. Unsprung weight is the total mass of components not supported by the suspension. This includes your tires, brakes, wheels, and each individual lug nut. Reducing this weight directly improves your suspension’s responsiveness. Your shocks have less mass to control. This allows your tire to maintain better contact with the road, which boosts grip and cornering ability. A lighter lug set also reduces rotational inertia.

Pro Tip: High unsprung mass can cause severe wheel hop during hard acceleration or braking. This compromises your traction and steering control. A lighter lug helps prevent this.

A reduction in unsprung mass affects acceleration and braking efficiency.

- Lighter components require less energy to speed up and slow down.

- Your engine works less to spin the wheels, resulting in quicker acceleration.

- Less mass allows for more effective braking and shorter stopping distances.

Material Strength for Enhanced Safety

The strength of your lug nuts is critical for safety. A stock lug might be fine for daily commuting. However, performance driving creates intense forces that demand a stronger lug. Aftermarket options made from forged steel or titanium provide superior material strength. This added strength ensures your wheels stay securely attached during aggressive cornering, rapid acceleration, and hard braking. While titanium is famous for its high strength-to-weight ratio, high-quality forged steel is often stronger overall. For example, some Grade 5 titanium lug nuts have a tensile strength of 150,000 PSI. This provides more than enough strength for demanding applications, giving you peace of mind when you push your vehicle to its limits. Choosing a lug with proven strength is a smart investment in your safety and your car’s tire integrity.

Steel vs. Aluminum vs. Titanium: Which Material is Best?

Choosing the right material for your lug nuts depends on your goals. You must balance durability, weight, and cost. Each material offers a unique set of advantages for different types of drivers.

Forged Steel: The Durable Daily Driver

Forged steel is the most common and practical choice for a lug nut. You get exceptional strength and durability at an affordable price. Steel can handle higher torque specifications without stripping. It is also highly resistant to the wear and tear of daily driving. This makes a steel lug a reliable option for most vehicles.

While steel is heavier than other materials, its toughness is unmatched. Manufacturers often add protective coatings to enhance its performance.

- Chrome Plating: This gives the lug a classic, shiny look while providing excellent protection against rust.

- Black Oxide: This coating offers good corrosion resistance. It does not change the dimensions of the part, making it great for precision fasteners.

- Dacromet Coating: This advanced finish provides superior corrosion resistance, often lasting over 500 hours in salt spray tests without causing hydrogen embrittlement.

Steel is the go-to material if your top priorities are strength and long-term reliability for your daily commute.

Forged Aluminum: The Stylish Lightweight

Forged aluminum is the perfect choice when you want to reduce unsprung weight and add visual flair. These lightweight nuts come in a wide variety of vibrant colors, giving your wheels a custom style. Manufacturers use a process called anodization to color the aluminum. This process integrates the dye directly into the metal’s surface, making the color resistant to chipping or peeling.

Buyer’s Tip: Be aware that some anodized colors, especially red, can fade over time with prolonged exposure to UV sunlight. Proper care helps maintain their bright appearance.

While an aluminum lug is not as strong as steel, high-quality 7075-T6 aluminum provides more than enough strength for spirited street driving and show car applications. It offers a fantastic balance of weight reduction and personalization.

Forged Titanium: The Ultimate Performance Upgrade

Forged titanium represents the pinnacle of performance for car tire nuts. This material offers the best of both worlds. You get the lightweight properties of aluminum combined with strength that often exceeds steel. Titanium’s incredible strength-to-weight ratio is why it is a top choice in aerospace and military applications. A titanium lug provides maximum security for your tire under the most extreme racing conditions.

The data clearly shows titanium’s superiority for performance applications.

| Property | 7075-T6 Aluminum | Grade 5 Titanium |

|---|---|---|

| Ultimate Tensile Strength (MPa) | 560 | 1000 to 1190 |

| Shear Strength (MPa) | 330 | 600 to 710 |

| Fatigue Strength (MPa) | 160 | 530 to 630 |

| Density (g/cm³) | 3.0 | 4.4 |

This level of performance comes at a price. A set of forged titanium lug nuts can cost around $199, making it a significant investment. However, for drivers who demand the absolute best in safety, durability, and weight savings, there is no substitute for a titanium lug.

How to Find the Best Aftermarket Lug Nuts for Your Vehicle

Choosing the best aftermarket lug nuts requires more than just picking a color or material. You must ensure the new hardware fits your vehicle and wheels perfectly. Proper fitment is essential for safety, performance, and preventing damage. This guide will help you navigate the technical details to make a confident choice.

Understanding Seat Type: Conical, Ball, and Mag

The “seat” is the contact area where the lug nut meets the wheel. This surface is crucial for distributing clamping force correctly. Using the wrong seat type creates a dangerous mismatch. The load gets focused on a tiny area, sometimes as little as 10% of the intended surface. This concentrated stress can cause the lug to wear down, lose torque, and potentially fail, leading to wheel loss. You must match your new lug to your wheel’s seat design.

There are three primary seat types:

- Conical Seat: This is the most common type for aftermarket wheels. The seat has a 60-degree taper, creating a cone shape that centers the lug in the hole. It is also known as a “tapered” or “acorn” seat.

- Ball Seat: This lug features a rounded or spherical seat. Many original equipment manufacturer (OEM) wheels, especially from Honda and Volkswagen, use this design. You should not use a conical lug on a ball seat wheel.

- Mag Seat: This type has a flat base with an extended shank. The shank fits into the lug hole to center the wheel, while the flat base provides the clamping force. A flat washer is almost always used with a mag seat lug.

Safety Alert: Never mix and match seat types. Using a conical lug on a ball seat wheel, or vice versa, is a leading cause of loose lug nuts. This incorrect installation can lead to severe tire damage or injury. Always verify your wheel’s seat type before buying a new lug set.

Matching Thread Pitch and Size

Every vehicle has a specific thread pitch and size for its wheel studs. This measurement determines which car tire nuts will fit. The specification is written as two numbers, like M12 x 1.5.

- The first number (M12) is the diameter of the stud in millimeters.

- The second number (1.5) is the thread pitch, or the distance between threads in millimeters.

Using a lug with the wrong thread pitch will cause serious damage. If you try to force it on, you will strip the threads on both the lug and the wheel stud, requiring a costly repair.

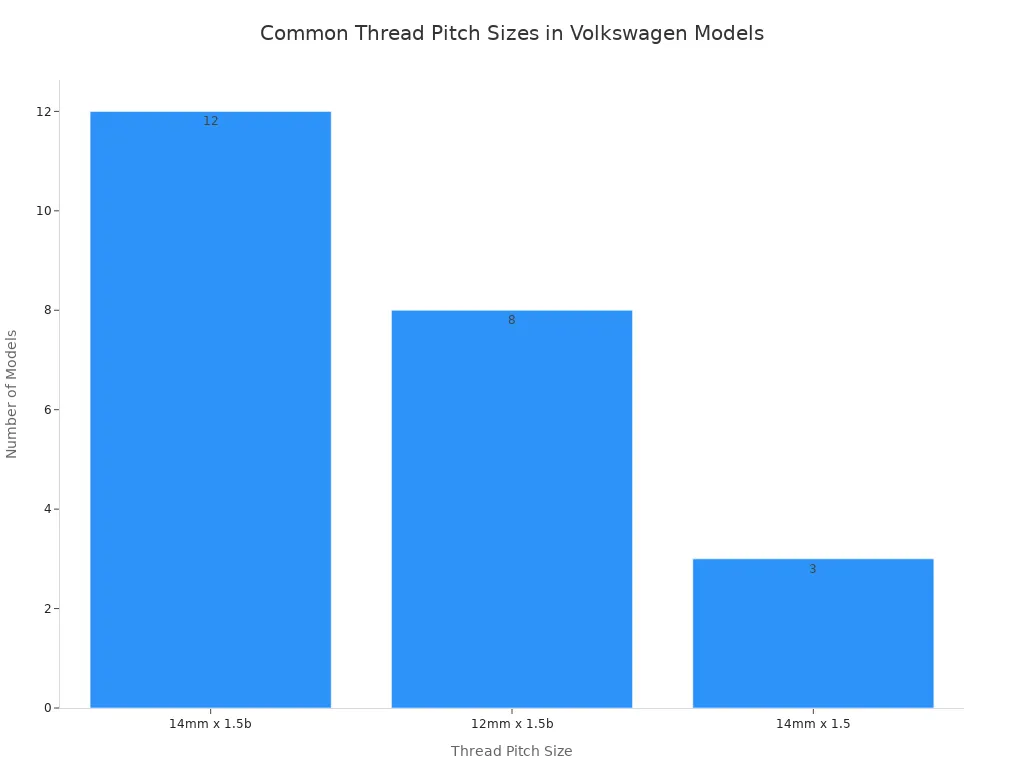

Common thread sizes vary by manufacturer. For example, many Japanese cars use M12 x 1.5, while many European cars use M14 x 1.5. The chart below shows how one manufacturer, Volkswagen, uses different thread pitches across its models.

Here is a table of common thread sizes you might encounter:

| Metric Sizes | Imperial Sizes |

|---|---|

| M12 x 1.25 | 7/16″ – 20 |

| M12 x 1.5 | 1/2″ – 20 |

| M14 x 1.25 | 9/16″ – 18 |

| M14 x 1.5 |

Finding Your Car’s Specifications

Finding the correct specifications for your vehicle is a straightforward process. You have several reliable options to get the information you need. A few minutes of research ensures you buy the right lug the first time.

Here are the best ways to find your car’s lug nut specs:

- Check Your Owner’s Manual: Your vehicle’s manual is the most reliable source. It often lists the thread size and sometimes the factory seat type.

- Inspect an Existing Lug Nut: Many factory lug nuts have the thread size stamped directly on them. Remove one and look closely for markings.

- Use a Thread Checker Tool: For a guaranteed accurate measurement, you can use a lug nut thread checker. These simple tools have male studs and female threaded holes for various sizes. You can test your existing lug against the male studs or test your wheel stud against the female holes to quickly identify the correct thread pitch.

- Consult Your Dealership or a Trusted Mechanic: Your local dealership’s parts department can look up the exact specifications for your vehicle’s make, model, and year.

Once you know your seat type and thread pitch, you are ready to choose the perfect aftermarket lug for your wheels.

A Guide to the Best Lug Nuts for Style and Security

After you determine the correct fitment, you can focus on style and security. The design of a lug nut affects both its appearance and its ability to protect your investment. You have important choices to make between open and closed designs and whether to add locking nuts.

Open-Ended vs. Closed-Ended Nuts

You will choose between two main lug designs: open-ended and closed-ended. A closed-ended lug has a capped end that protects the wheel stud from dirt, water, and rust. This makes it a great choice for most daily drivers. An open-ended lug is open on both sides, allowing the wheel stud to pass completely through it.

Both types of lug nuts come in a huge variety of designs to match your personal style. Current trends show a high demand for aesthetic customization.

- Popular Styles: Splined, spike, and colored lug nuts are very popular.

- Advanced Finishes: PVD (Physical Vapor Deposition) coatings offer superior corrosion resistance and more color options than traditional chrome.

- Lightweight Materials: Many drivers prefer aluminum and titanium for their weight savings and performance look.

These options help you find the best lug nuts to complement modern wheel finishes, such as satin black or two-tone designs.

The Importance of Locking Lug Nuts

Protecting your wheels is more important than ever. Law enforcement reports show a significant increase in wheel theft, with a rise of over 30% in major cities like Houston and Atlanta. A set of locking lug nuts is a simple and effective deterrent. One lug on each tire is replaced with a special locking lug that requires a unique key for removal.

Not all locking lug designs offer the same security. A spline drive lug is considered less secure because the tools are more common. A lug with a unique, computer-generated key pattern provides much better protection. Some high-security designs even feature a rotating outer collar that spins freely if a thief tries to grip it with standard tools. Adding a quality locking lug set gives you peace of mind and helps keep your valuable wheels safe.

Top Brand Recommendations for Every Driver

Choosing the right brand is the final step in your upgrade. Your driving needs will guide you to the perfect set. Some brands focus on extreme durability, while others prioritize custom style. Finding the best lug nuts means matching a brand’s strengths to your goals.

Best for Durability and Daily Use: Gorilla & McGard

You need reliability for daily driving. Gorilla and McGard are top choices for strength and durability. The Gorilla brand has a strong reputation for making a dependable lug. Many drivers trust a Gorilla lug for its performance. A Gorilla lug is built for longevity. The Gorilla Automotive brand offers excellent durability. You can count on a Gorilla lug. Gorilla is a name you can trust. The Gorilla brand is a solid choice. Gorilla makes a great lug.

McGard also offers exceptional quality. The McGard brand is known for its clever engineering.

- A McGard lug often has a two-piece design.

- This design prevents scratches on your wheels.

- It also helps you get more consistent torque.

For truck owners, McGard provides heavy-duty options. You can get a McGard set like Part Number 52003 for a tandem axle tractor. This McGard kit gives you ultimate security and durability.

Best for Style and Show Cars: Muteki

You want your wheels to stand out. Muteki is a fantastic choice for adding custom style. This brand offers a wide range of colors to personalize your vehicle. You can find a Muteki lug in vibrant shades.

- SR35 (Closed-End): These come in Black, Red, Blue, Purple, and Chrome Neon.

- SR48 (Open-End): These are great for extended studs and come in finishes like Neochrome.

A Muteki lug lets you create a unique look. The brand gives you the best options for visual flair and style.

Best for Ultimate Performance: Vossen

You demand the absolute best performance. Vossen creates some of the best lug nuts for racing and high-stress applications. This brand focuses on premium materials like forged titanium. A Vossen lug provides the ultimate combination of low weight and high strength. This makes them a top-tier choice for drivers who need every possible advantage on the track.

Proper Installation and Maintenance for Longevity

You can extend the life of your new hardware with correct installation and care. Proper procedures protect your investment and ensure your wheels remain secure. Following these steps enhances both safety and the durability of your components.

The Importance of Hand-Torquing

You must install your new lug nuts correctly. Never use an impact wrench to fully tighten a lug. An impact wrench can easily apply too much force. This can stretch the threads on your wheel stud or strip the threads inside the lug. Over-tightening also puts stress on your wheel, which can lead to damage. The best tool for the job is a torque wrench. It allows you to apply the exact amount of pressure your car manufacturer recommends.

Installation Pro-Tip: Always tighten each lug in a star pattern. This method applies even pressure across the wheel hub. It ensures the wheel seats correctly and prevents warping your brake rotors. A properly torqued lug is essential for safety.

Using a torque wrench guarantees each lug receives the same clamping force. This precision is critical for performance and the long-term durability of every lug.

Regular Inspection and Care

Your work is not finished after the initial installation. You need to re-check the torque on each lug nut. Wheels can settle after being driven, causing a slight loss in torque. It is a standard safety practice to re-torque your wheels after a short distance. Many tire shops, including Costco, ask you to return for a free torque check after 50 miles. This practice is also common in Germany, where drivers check torque after 50 kilometers.

For maximum safety, follow this re-torquing schedule:

- Check and re-torque each lug after the first 10 miles.

- Check and re-torque the lug set again at 25 miles.

- Repeat the process one last time at 50 miles.

- Check the lug nuts periodically after that as part of your regular vehicle maintenance.

Regular cleaning also helps. Keep the lug and stud threads free of dirt and rust. This ensures you get an accurate torque reading every time you check your single tire.

You can easily boost your car’s performance, safety, and style. Upgrading your car tire nuts is a smart, cost-effective change. Your success depends on choosing the right lug for your specific wheels. You must match the lug material and seat type correctly.

A quality lug is a small part that makes a big impact. Don’t let a stock lug be the weak link for your tire. Unlock your vehicle’s full potential by investing in a set of aftermarket lug nuts. Every single lug contributes to a better driving experience. A strong lug is a safe lug.

FAQ

Can I use an impact wrench to install my new lug nuts?

You should never use an impact wrench for final tightening. Use it only to snug the lug nuts. Always use a calibrated torque wrench for the final step. This prevents damage to the lug and ensures safety.

Why is Gorilla a good choice for a daily driver?

The Gorilla brand is excellent for daily use. A Gorilla lug is known for its strength and durability. Many drivers trust a Gorilla lug for its reliability. The Gorilla brand makes a tough lug. You can depend on a Gorilla lug. Gorilla is a top choice.

How often should I check my lug nut torque?

You should re-check your lug torque after the first 10, 25, and 50 miles of driving. After that, you can check each lug as part of your regular vehicle maintenance schedule. This ensures every lug remains secure.

What is the main benefit of an open-ended lug?

An open-ended lug allows extended wheel studs to pass through. This design is essential for many track cars. It lets you easily inspect thread engagement, which is a common safety requirement for racing events.