admin1

January 15, 2026

Are any black lug nuts that don’t rust?

Yes, some black lug nuts do not rust. Rust-resistant properties help maintain the safety and appearance of the lug nuts. Automotive experts say that rust-resistant lug nuts offer many advantages:

- Corrosion-resistant lug nuts have a longer lifespan.

- In rainy regions, rust-resistant lug nuts ensure wheel safety.

- Choosing rust-resistant lug nuts saves money on buying new ones.

With rust-free lug nuts, drivers can drive with peace of mind and enjoy a good driving experience.

Key Takeaways

- Choose black lug nuts made of stainless steel or aluminum. These metals are less prone to rusting.

- Choose lug nuts with a good coating (such as PVD or powder coating). These coatings help prevent water and rust.

- Clean the lug nuts regularly with a non-acidic cleaner. This keeps them looking good and prevents rust.

- Make sure the size and seat type of the lug nuts match your car. This is crucial for safety.

- Buy from a trusted brand, such as Gorilla or McGard. These brands offer durable and high-performing lug nuts.

What Makes Black Lug Nuts Rust-Proof

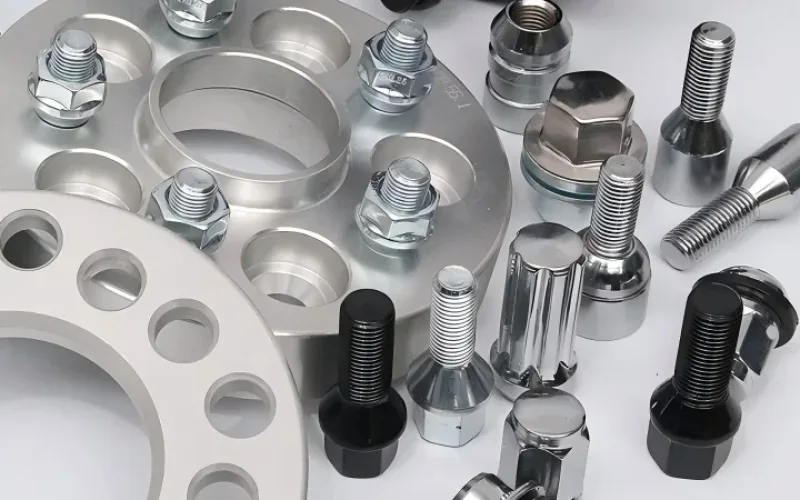

Materials That Prevent Rust

Manufacturers use special materials to keep black lug nuts strong and rust-resistant. Stainless steel and aluminum stand out for their excellent corrosion resistance.

- Stainless steel undergoes passivation. Workers clean the metal, immerse it in an acid solution, and then let it dry. This creates a protective layer that prevents rusting.

- Aluminum undergoes anodizing. This means a hard oxide layer forms on the surface. The process involves cleaning, pretreatment, anodizing, coloring, and sealing. The resulting lug nuts are rust-resistant and have a longer lifespan.

These materials help black lug nuts remain safe in humid or salt spray environments. Drivers trust their durability and protective properties.

Coatings for Rust Resistance

Coatings play a vital role in maintaining the appearance and rust resistance of black lug nuts. Many companies use advanced coatings, such as PVD (Physical Vapor Deposition), powder coating, or black zinc plating.

- PVD coatings create a hard, smooth surface that blocks moisture and chemicals.

- Powder coating adds a thick protective layer that prevents chipping and scratching.

- Black zinc plating provides extra rust protection, especially in harsh weather conditions.

Not all coatings are created equal. Some paint coatings may look good initially but wear off quickly. Choosing nuts with a high-quality coating provides better protection and a longer lifespan.

Durability of Black Finishes

The strength of the black coating is crucial for rust prevention.

- The black oxide layer is thin and easily wears off due to friction.

- It requires additional protection, such as oiling or waxing, to prevent rust.

- Regular maintenance is important. If the owner forgets to reapply the protective layer, rust can appear quickly.

A durable coating keeps black nuts looking new and performing well. Those who want the best results should choose nuts with a robust coating and perform regular maintenance.

Best Black Lug Nuts That Don’t Rust

Top Recommended Brands

Car owners looking for black lug nuts that won’t rust will choose trusted brands. These companies are known for producing strong and durable products.

- Gorilla produces lug nuts that are strong, durable, and offer excellent rust resistance.

- McGard’s Tough Nuts offer a lifetime warranty against chipping, peeling, and rusting.

- Fortune offers high-quality lug nuts with special coatings and rigorous quality testing.

- Tough Nuts are made in the USA and meet strict safety standards.

Many also like Black Spline Lug Nuts and Black Acorn Spline Lug Nuts. These nuts use rust-resistant materials and a closed-end design to prevent water and salt from entering the wheel studs. The strong steel and durable black coating help these nuts remain rust-free and keep the wheels looking good.

What to Look For Black lug nuts

To choose lug nuts that won’t rust, buyers need to check a few important things. Material, coating, and warranty information should be reviewed before purchasing.

| Feature | Description |

|---|---|

| Thread Size | Must fit your car’s wheel studs (like M14x1.25 or 1/2”-20). |

| Seat Type | Make sure your wheels need conical, ball, or flat seat lug nuts. |

| Shank Length | Shows how far the lug nut covers the stud. |

| Material | Choices are chrome vanadium steel, stainless steel, or titanium. |

| Finish | Black oxide, zinc plating, or chrome help stop rust. |

| Torque Specification | Check if it matches the right torque (80–120 ft-lbs). |

Buyers should choose nuts with PVD coating, stainless steel caps, or powder-coated surfaces. These features provide better rust protection and help extend the lifespan of the nuts. A lifetime warranty provides peace of mind for buyers and demonstrates the company’s confidence in its product.

Black lug nuts Comparing Features

Viewing different black lug nuts helps buyers choose the most suitable product. The table below shows a comparison of warranty and rust resistance performance for different products.

| Product Description | Warranty | Rust Resistance |

|---|---|---|

| Spline Lug Nuts | 1 Year | 72-200 hours NSS test |

| Best Tuner Style | 1 Year | Good anti-rust performance |

| Black OE Style | Limited Lifetime | Corrosion-resistant coating |

Lug nuts with stainless steel caps offer excellent rust resistance. These nuts rarely rust, even after many years. Chrome-plated nuts look nice, but they will rust quickly if the plating is damaged.

McGard Tough Nuts are built to last. They won’t chip, peel, or rust. We guarantee they will stay shiny for years. Our Tough Nuts are made in the USA and meet the highest safety and strength standards. They feature a triple-layer nickel-chrome plating for beauty and durability. Our expert team uses our own electroplating process. Each nut comes with a written lifetime warranty.

Many customers report that their lug nuts rust and chip, especially when overtightened. Durable lug nuts are especially important during harsh winter conditions. Gorilla and Fortune address these issues with special coatings and rigorous testing. Drivers who choose rust-resistant black lug nuts can achieve better results and extend the life of their wheels.

How to Choose Black Lug Nuts That Won’t Rust

Black lug nuts Key Selection Criteria

Consumers want to buy black lug nuts that are durable and maintain their appearance. They should focus on three main factors: material, safety, and corrosion resistance.

- Choose lug nuts made of stainless steel or chrome-plated steel. These metals can withstand harsh weather conditions and prevent rust.

- Check if the lug nuts meet safety standards. Reputable brands usually list these details.

- Look for coatings that offer extra protection. PVD and powder coatings help the nuts resist chipping and moisture.

Tip: Stainless steel and chrome-plated steel offer both strength and rust resistance. Aluminum and titanium are also good options for drivers who want a lightweight choice.

Vehicle Compatibility

Every vehicle requires the correct lug nuts. Buyers should match the thread size, seat type, and shank length to their vehicle.

- The thread size must match the wheel studs.

- The seat type should match the wheel design.

- The shank length should cover the stud to ensure secure installation.

The table below lists common materials and their characteristics:

| Material | Properties |

|---|---|

| Steel | Strong and durable |

| Chrome-plated steel | Added corrosion resistance and sleek finish |

| Stainless steel | Excellent rust resistance |

| Aluminum | Lightweight, favored in high-performance vehicles |

| Titanium | Lightweight, high strength |

Choosing the appropriate material allows drivers to ensure wheel safety and avoid problems on the road.

Black lug nuts Price vs. Quality

When buying black wheel nuts, quality is crucial. While cheaper options might save money now, they will cost more in the long run if they rust or become damaged.

- A set of four to six replacement nuts costs $15-40.

- Anti-theft nuts cost $25-60.

- Buying in bulk is more cost-effective for those with high volume needs.

| Price Range | Description |

|---|---|

| $15–$40 USD | Replacement wheel nuts for a set of four to six |

| $25–$60 USD | Locking versions |

| Varies by Region | Higher in remote markets due to import costs |

| Varies by Brand | OEM-style branded sets command premium pricing |

| Varies by Finish | Chrome-plated sets are slightly more expensive |

| Better Value | Bulk packs (10–20 pcs) offer better value |

Buyers who purchase high-quality wheel nuts can enjoy a longer lifespan and better rust protection. High-end brands often offer warranties and more durable finishes. Savvy consumers choose quality over price for peace of mind and lasting performance.

Keeping Black Lug Nuts Rust-Free

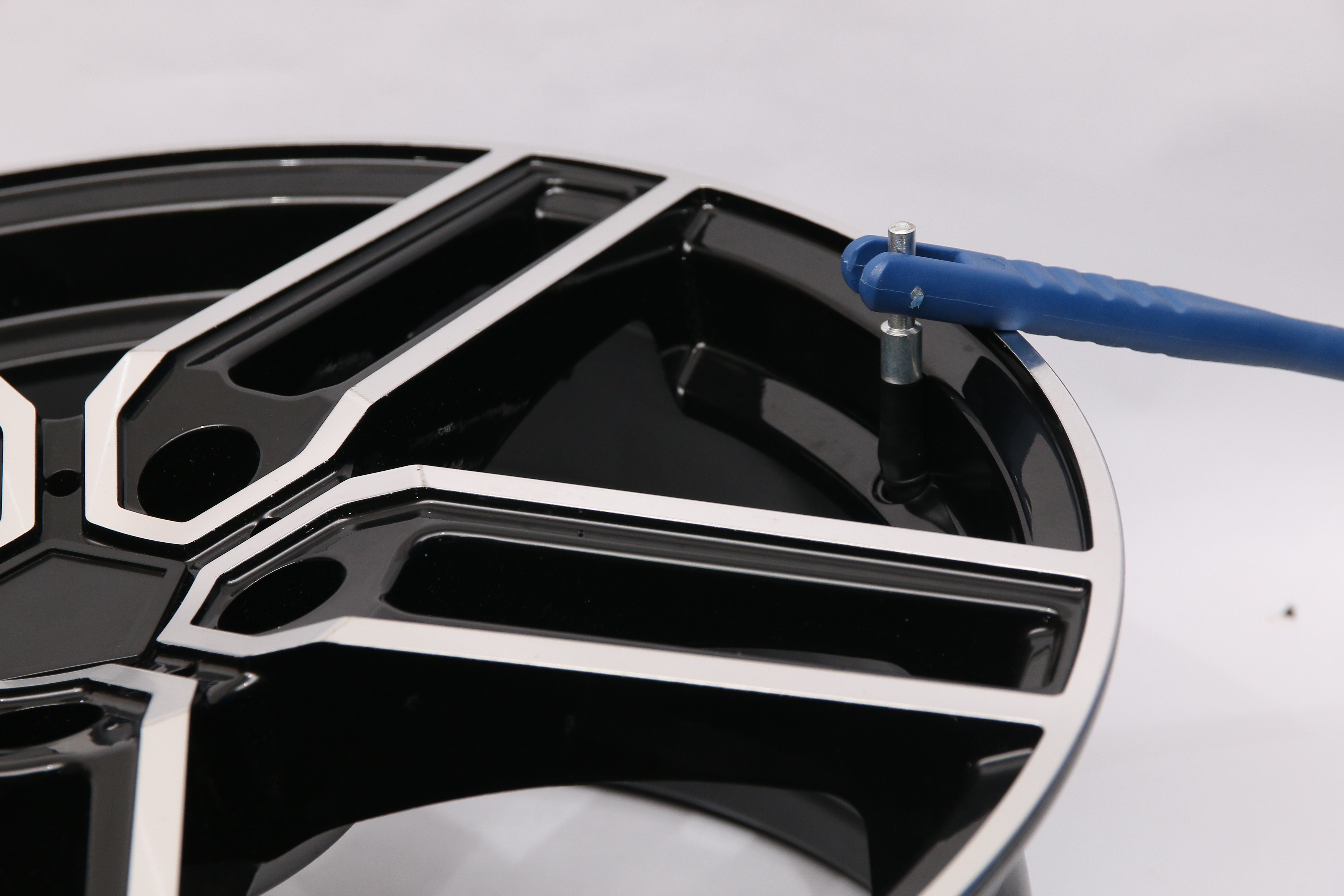

Black lug nuts Installation Tips

Proper installation protects black wheel nuts from damage and helps prevent rust. Mechanics recommend using a torque wrench instead of an impact wrench. This tool applies even pressure, preventing overtightening and thus avoiding coating cracks. Using a protective sleeve or wrapping the nuts with masking tape also helps prevent scratches during installation.

Many experts advise against using an impact wrench, as it can damage the coating, exposing the metal to moisture. Using the correct size socket is also important. An ill-fitting socket can cause uneven pressure and expansion of the nut, leading to problems later on.

Tip: Always check for proper fit before tightening. The correct size protects the coating and ensures the nut is secure.

Black lug nuts Maintenance Practices

Regular cleaning keeps black lug nuts looking like new and prevents rust. Owners should use a non-acidic wheel cleaner. Acidic products can corrode the protective coating, exposing the metal. Use a soft-bristled brush to clean the area around the lug nuts, avoiding scratching the surface. After cleaning, dry with a hairdryer to prevent water stains and avoid moisture retention on the metal surface. Avoid using harsh chemicals and abrasive tools. These substances will wear down the surface coating, making rust more likely.

- Use a non-acidic wheel cleaner

- Use a soft-bristled brush for cleaning

- Dry after cleaning

Regular maintenance is crucial. Drivers who frequently clean their wheels rarely encounter problems with rusty lug nuts.

Black lug nuts Environmental Factors

Weather and road conditions affect how long black nuts remain rust-free. Humidity accelerates rusting because moisture reacts with the metal. In winter, road salt increases the risk of corrosion. Salt adheres to the wheels and corrodes the surface coating. Even the best coatings require extra protection in harsh environments.

- Rusting and corrosion occur when metal comes into contact with oxygen and moisture.

- Humidity increases moisture, thus accelerating rusting.

- Road salt in winter makes corrosion more severe.

Drivers living in humid or snowy areas should clean their wheels more frequently. Timely cleaning keeps black nuts in optimal condition and prevents them from rusting.

Rust-proof black nuts do exist. The right materials and coatings are crucial. Electroplated black nickel is less likely to peel or rust. It performs better than painted or powder-coated finishes.

| Material/Coating Type | Resistance to Chipping | Resistance to Corrosion |

|---|---|---|

| Electroplated Black Nickel | High | High |

| Painted Finish | Low | Moderate |

| Powder-Coated Finish | Moderate | Low |

Drivers who maintain their nuts save money. Their wheels last longer. Regularly cleaning the nuts helps maintain their appearance. Harsh chemicals should be avoided. Wiping the nuts after washing the car keeps them looking new and rust-free.

FAQ

What makes black lug nuts rust-resistant?

Manufacturers choose durable metal materials such as stainless steel and aluminum. They also use coating technologies such as PVD coating or powder coating. These coatings are waterproof and prevent rust.

How often should car owners clean black lug nuts?

Car owners should clean the lug nuts monthly. Cleaning removes dirt and salt. Developing a regular cleaning habit keeps the lug nuts shiny and prevents rust.

Are all black lug nuts rust-resistant?

Not all black lug nuts are rust-resistant. Only those made with high-quality coatings and durable metal materials are effectively rust-resistant. Consumers should carefully read product details before purchasing.

Can rust-resistant lug nuts improve safety?

Yes! Rust-resistant lug nuts remain tight and secure. They protect the wheels from damage. Car owners can enjoy a safer driving experience and save on repair costs.

Which brands offer the best rust-resistant black lug nuts?

| Brand | Rust Resistance | Warranty |

|---|---|---|

| Gorilla | Excellent | 1 Year |

| McGard | Lifetime | Lifetime |

| Fortune | Superior | Quality Tested |

Tip: Choose a trustworthy brand for better results and peace of mind.