admin1

August 1, 2025

What You Need to Know About Air Valve Stem Types and Upkeep

You depend on the air valve stem to keep your tyres safe and ready for travel. The valve stem allows you to check your car tyre valve pressure and add air when needed. Each car tyre valve acts as a small gate, holding air inside your tyre and keeping the tire firm. If you notice a slow leak or soft tyre, check the valve for signs of damage.

Tip: A healthy valve stem helps prevent tyre problems and keeps your car tyre valve working longer.

Main Air Valve Stem Types

Schrader Valve Stems

You will find Schrader valve stems on most passenger vehicles around the world. This type of air valve stem uses a spring-loaded poppet valve. When you press down on the valve core, air flows in or out. Once you release it, the spring closes the valve and seals the tyre. Schrader valves have a wider diameter, usually about 8 mm, which makes them strong and easy to use. You can inflate tyres with a wide range of pumps because of this design.

Tip: Schrader valves are very durable. You can use them on rough roads and in tough conditions without worrying about damage.

Schrader valve stems are popular because they are simple to install and maintain. You will see them on cars, trucks, and even some bicycles. The market for these valve stems is large, especially in North America and Europe, where the automotive industry is well established. Passenger cars hold about 45% of the global market share for valve stems. The table below shows more details about the market:

| Category | Details |

|---|---|

| Valve Stem Types | Straight (largest market share), L-shaped (growing), T-shaped (notable share), Custom (niche) |

| Materials | Natural Rubber, Synthetic Rubber (EPDM, Nitrile), Metal, Composite |

| Vehicle Segment | Passenger Cars dominate with ~45% market share globally (2023) |

| Regional Market Share | North America: ~38.5%, Europe: ~30.2%, Asia-Pacific: fastest growth expected |

| Market Growth | CAGR of 5.5% (2025-2034), projected valuation USD 2.34 billion by 2034 |

| Key Players | Schrader International, Presta Valve Stem Company, Goodyear, Bridgestone, Continental AG |

Schrader valve stems are easy to inflate and compatible with many pumps. You can remove the valve core for cleaning or replacement. These valves are more prone to air leakage than some other types, so you should check your tyre pressure often. Still, their durability and ease of installation make them a top choice for many drivers.

Presta Valve Stems

Presta valve stems look different from Schrader valves. You will notice they are thinner, with a diameter of about 6 mm. This narrow size helps keep bicycle rims strong, especially on lightweight or racing bikes. Presta valves use a small screw and captive nut at the top. You must unscrew the nut to let air in or out, then tighten it to seal the valve.

Presta valves are common on road bikes, high-end mountain bikes, and racing bicycles. You can find them in different lengths to fit deep-section rims. The design allows for a secure seal and fine air pressure adjustments. Some Presta valves have removable cores, so you can add sealant for tubeless tyres.

- Presta valves fit rims drilled for Presta without weakening them.

- You can use longer Presta valves (up to 80 mm) for deep rims.

- Presta valves work in Schrader-drilled rims with an adapter, but not the other way around.

- The smaller hole size helps keep rims strong and improves aerodynamics.

- Presta valves allow easy air release and resist dirt better than some other valves.

Note: Presta valves are lighter than Schrader valves. This makes them a favorite for cyclists who want to reduce weight and keep their wheels strong.

You will see Presta valves mostly on bicycles, but their design shows how selecting the right valve type can improve performance and safety.

Tubeless Snap-In Valve Stems

Tubeless snap-in valve stems are a modern choice for many vehicles. You will find them on cars, trucks, and some bicycles that use tubeless tyres. These valve stems are made from strong rubber or synthetic materials. You can install them quickly by pushing them into the rim hole until they snap into place.

Tubeless snap-in valves offer several advantages:

- You can use a click-on pump system, which makes inflation easy.

- Minimal air loss occurs during pump attachment (about 0.1 PSI).

- You do not lose air when removing the pump.

- Most pumps work with these valves, except some Presta-only pumps.

- Adapters are available for even more compatibility.

- Even young or inexperienced users can operate these valves easily.

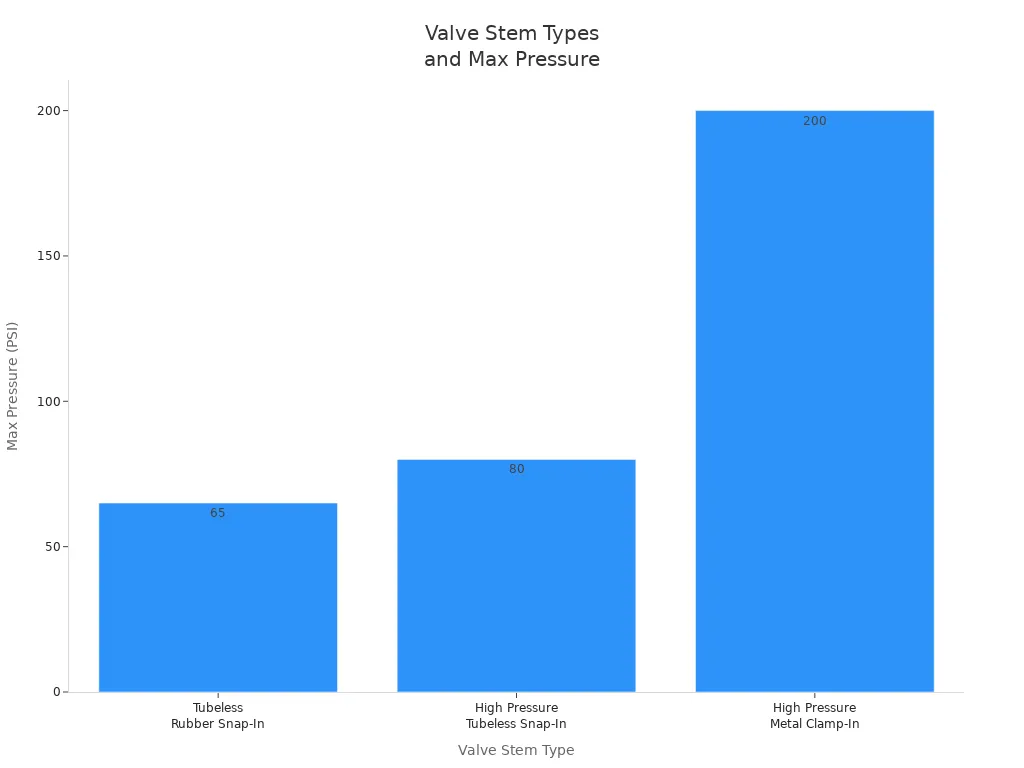

Tubeless snap-in valve stems are rated for a maximum pressure of 65 psi. High-pressure versions can handle up to 80 or even 100 psi, depending on the rim hole size. The table below shows the recommended pressure limits:

| Valve Type | Maximum Cold Inflation Pressure (psi) |

|---|---|

| Standard Tubeless Rubber Snap-In Valves (various sizes) | 65 psi |

| High-Pressure Snap-In Valves for .453″ rim holes | 80 psi |

| High-Pressure Snap-In Valves for .625″ rim holes | 100 psi |

Alert: Always check the pressure rating before installation. Using the correct valve stem helps prevent leaks and keeps your tyre safe.

You will find that rubber valve stems are common in tubeless snap-in designs. They provide flexibility and a tight seal. When you choose this type of air valve stem, you get easy installation and reliable performance for most everyday driving needs.

Metal Clamp-In Valve Stems

You will often see metal clamp-in valve stems on high-performance vehicles, heavy-duty trucks, and cars that need extra durability. These valve stems use brass or nickel-coated metal, which gives them superior strength compared to rubber snap-in types. You can rely on them in harsh environments because they resist heat, road chemicals, and UV damage. Their design helps prevent leaks and keeps your tyre pressure stable, even at high speeds.

- Metal clamp-in valve stems handle much higher pressures, often up to 160 PSI and sometimes as high as 200 PSI.

- You secure these valve stems with a retaining nut and a rubber grommet, which creates a tight seal against the wheel.

- You need a wrench for installation, and you must use new seals and nuts each time to avoid leaks.

- These valve stems are essential for vehicles with TPMS, off-road vehicles, SUVs, and trucks that carry heavy loads.

Tip: Always use the correct torque when tightening the retaining nut. Over-tightening can damage the nut and cause leaks.

You will find that metal valve stems last longer than rubber ones. Their metal construction stands up to extreme heat and pressure. You can check and adjust the retaining nut without removing the tyre, which makes maintenance easier. Although installation takes more time and skill, you get better safety and reliability for demanding driving conditions.

| Feature | Metal Clamp-In Valve Stem | Rubber Snap-In Valve Stem |

|---|---|---|

| Material | Brass or nickel-coated metal | Rubber or synthetic rubber |

| Pressure Handling | Up to 200 PSI | Up to 65 PSI |

| Durability | High | Moderate |

| Leak Prevention | Excellent (with proper installation) | Good (may degrade over time) |

| Installation | Requires wrench and new seals | Simple push-in |

| Best Use | High-performance, heavy-duty, TPMS | Everyday passenger vehicles |

You should always replace the rubber grommet and nut during installation. Reusing old parts can lead to slow leaks. Metal clamp-in valve stems give you peace of mind when you drive in tough conditions or at high speeds.

High-Pressure Valve Stems

High-pressure valve stems are built for vehicles that need to handle extreme loads or speeds. You will see these on commercial trucks, rugged light trucks, and sports cars. These valve stems can withstand pressures up to 200 PSI, making them perfect for tyres that support heavy trailers or race at high speeds.

| Valve Stem Type | Pressure Range (PSI) | Common Vehicle Categories |

|---|---|---|

| Tubeless Rubber Snap-In Valves | Up to ~65 PSI | Most passenger vehicles, small to medium trucks, SUVs |

| High Pressure Tubeless Snap-In | Above 65 PSI, up to 80 PSI | Bigger trucks, heavy-duty tires |

| High Pressure Metal Clamp-In | Up to 200 PSI | Heavy-duty commercial trucks, rugged light trucks hauling heavy loads or towing trailers, high-performance vehicles (sports cars, race cars) |

You can see that high-pressure valve stems are not just for trucks. Sports cars and race cars also use them because they need reliable air retention at high speeds. These valve stems use strong metal construction and a secure clamp-in design. You get better safety, especially when your tyres face extreme heat or heavy loads.

You should always check the pressure rating before choosing a valve stem for your tyre. Using the right type helps prevent blowouts and keeps your TPMS working accurately. High-pressure valve stems are a must for anyone who drives in demanding conditions or needs extra peace of mind on the road.

Specialty Valve Stems (TPMS, Chrome-Sleeve, Motorcycle, and Bicycle Valves)

Specialty valve stems serve unique needs for different vehicles and tyre types. You will find TPMS valve stems on most modern cars. These work with your tyre pressure monitoring system to give real-time pressure updates. TPMS valve stems come in both snap-in rubber and metal clamp-in styles. You need the right type to ensure your TPMS sensors work correctly and keep you safe.

Chrome-sleeve valve stems add a stylish look to your wheels. You can use them to match custom rims or enhance your vehicle’s appearance. These valve stems often use a metal core for strength and a chrome finish for style.

Motorcycle and bicycle valve stems come in different shapes and sizes. You will see rubber snap-in stems on most motorcycles, which handle up to 65 PSI. Bicycles use both Schrader and Presta valves. Presta valves are common on racing bikes because they are lightweight and allow precise air adjustments.

| Vehicle Type | Valve Stem Type | Pressure Rating | Temperature Rating | Contribution to Tire Pressure Monitoring and Safety |

|---|---|---|---|---|

| Passenger Vehicles | Snap-in Rubber | Up to 65 psi | -40°F to 180°F | Flexible, easy installation; suitable for lower pressure; supports basic TPMS function |

| Heavy-Duty Trucks | Metal Clamp-in | Up to 200 psi | -65°F to 250°F | Enhanced durability and heat resistance; reduces leaks and valve failure; critical for accurate TPMS and safety |

| Motorcycles | Rubber Snap-in | Up to 65 psi | -40°F to 180°F | Adequate for lower pressure; supports TPMS accuracy |

| Tractors/Off-Road | High-Pressure Metal | 100+ psi | Extreme temperature range | Handles rugged conditions; ensures air retention and TPMS reliability |

You should always choose the right valve stem for your tyre and vehicle. Proper selection and installation prevent leaks and help your TPMS work as designed. Specialty valve stems play a big role in keeping your tyres safe, your pressure accurate, and your ride smooth.

Note: Regular inspection and correct installation of specialty valve stems help maintain tyre pressure and extend tyre life.

How Air Valve Stems Function

Basic Design and Components of a Car Tyre Valve

You rely on the car tyre valve every time you check your tire pressure or add air. The design of a car tyre valve includes several important parts, each with a specific function. The table below shows the main components and their roles:

| Component | Function |

|---|---|

| Valve Cap | Protects the valve stem from dirt, debris, and moisture; prevents damage and air loss; acts as a secondary seal. |

| Valve Core | Main sealing device inside the valve stem; regulates air pressure by allowing air in or out; prevents air escape when closed; contains a spring-loaded pin. |

| Valve Stem | Acts as the passageway for air to flow into and out of the tire; houses the valve core. |

| Valve Extension | Optional component used to facilitate easier access for inflation or pressure checks. |

Each car tyre valve uses these parts to keep air inside the tire and block out dirt or water. The valve cap is small but very important. It helps prevent leaks and keeps the car tyre valve clean. The valve core sits inside the stem and controls the flow of air. The stem itself forms the main body of the car tyre valve, giving you a strong and reliable passage for air.

Role in Tire Inflation and Pressure Retention

The car tyre valve serves as a sealed passage for air to enter and stay inside your tire. When you inflate your tire, air moves through the car tyre valve and fills the tire chamber. The valve core closes tightly after inflation, locking the air inside. This function keeps your tire firm and ready for the road.

If the car tyre valve becomes damaged or corroded, it can lose its ability to hold air. Corrosion weakens the metal parts, which may cause sudden air loss. You need to keep the car tyre valve in good condition to avoid leaks and keep your tire pressure steady. A healthy car tyre valve helps your tire last longer and keeps your ride safe.

Importance for Vehicle Safety and Performance

You cannot ignore the importance of valve maintenance. The car tyre valve plays a big role in your safety and the performance of your vehicle. Here are some key reasons:

- The car tyre valve keeps your tire inflated, which is vital for safe driving, longer tire life, and better fuel use.

- Cracks at the base of the car tyre valve can cause leaks and sudden tire deflation, which may lead to accidents.

- Low-quality car tyre valves can wear out quickly, so you should always choose high-quality parts.

- Different car tyre valve types have different pressure ratings and build quality, which affects how safe and durable they are.

- Regular car tyre valve checks and using quality replacements help prevent leaks and keep tire pressure at the right level, improving both safety and performance.

You can follow these tips to keep your car tyre valve working well:

- Always tighten the valve cap to block dirt and moisture.

- Replace missing valve caps right away.

- Install a new car tyre valve when you get new tires.

A well-maintained car tyre valve helps prevent blowouts, keeps your tire pressure correct, and supports smooth driving. You protect your tires and your safety by paying attention to the car tyre valve.

Tyre Valve Maintenance Tips

Regular Inspection for Damage or Wear

You should make tyre valve maintenance a regular part of your routine. Inspecting your valve stems helps you catch problems before they turn into bigger issues. Look for cracks, splits, or signs of aging on the rubber. If you see any damage, the valve may not seal properly, which can lead to air leaks and unsafe driving conditions.

During your inspection, check for these common signs of valve stem deterioration:

- Cracks or splits in the rubber

- Hardening or brittleness of the valve stem

- Leaks around the base of the valve

- Missing or damaged valve caps

- Dented, broken, or deteriorated valve seals

You should also check for unusual tire pressure drops. If you notice your tyres lose air quickly, the valve could be defective. Make sure to inspect the spare tyre as well. Many people forget about it, but it needs the same attention as the others.

Tip: Inspect your valve stems every time you check air pressure or rotate your tyres. Early detection of a defective valve can prevent flats and keep your tyres safe.

Cleaning and Preventing Debris Buildup

Keeping your valve stems clean is a key part of tyre valve maintenance. Dirt, dust, and road debris can collect around the valve and cause leaks or make it hard to inflate your tyres. You should wipe the valve area with a clean cloth during each tyre wash. If you see any buildup, use a soft brush to remove it gently.

Valve caps play a big role in keeping debris out. Always keep a cap on each valve stem. The cap blocks dirt and moisture, which helps prevent corrosion and keeps the valve working well. If you lose a cap, replace it right away.

Lubrication also helps with valve maintenance. Apply a small amount of silicone-based lubricant to the valve stem once a year. This periodic lubrication keeps the rubber flexible and helps prevent cracking. Avoid petroleum-based products, as they can damage the rubber and shorten the life of the valve.

Note: Clean valve stems and proper lubrication help extend the life of your tyres and reduce the risk of leaks.

When and How to Replace Air Valve Stems

You need to know when to replace your valve stems to keep your tyres safe. Industry guidelines recommend replacing valve stems every time you get new tyres. You should also replace any valve that shows signs of cracking, leaking, or other damage. If you have a high-pressure tyre or a tyre with a TPMS sensor, use a replacement valve stem that matches the wheel type and pressure rating.

Follow these steps for safe and effective valve stem replacement:

- Gather the correct tools, such as a valve core tool and a flexible cable tool for tight spaces.

- Deflate the tyre completely before removing the old valve stem.

- Remove the old valve stem carefully to avoid damaging the rim or TPMS sensor.

- Inspect the rim hole for damage or debris before installing the new valve.

- Use a small amount of factory-approved lubricant on the new valve stem to ensure smooth insertion.

- Insert the new valve stem and make sure it seats properly.

- For metal clamp-in valves, tighten the retaining nut to the specified torque.

- Install a new valve cap to protect the valve from dirt and moisture.

- Inflate the tyre and check for leaks by applying soapy water around the valve area.

You should always use valve stems that meet industry standards, such as SAE 1205-1206, and are made under ISO9000 certifications. This ensures quality and safety. For high-pressure tyres, select a valve stem rated for the correct pressure. If you notice a defective valve or experience frequent air loss, replace the valve immediately to avoid tyre failure.

Callout: Preventive maintenance, including regular inspection, cleaning, and timely replacement, helps you avoid unexpected tyre problems and keeps your vehicle running smoothly.

Troubleshooting Common Valve Stem Issues

You may notice tyre problems even when your tread looks fine. Many issues start with the valve stem. Understanding the most common problems and how to fix them helps you keep your tyres safe and your vehicle running smoothly. Good tyre valve maintenance prevents many of these issues before they become serious.

Most Common Valve Stem Problems

You can spot several frequent valve stem issues during regular tyre valve maintenance:

- Valve stem seal failures often cause leaks around the valve stem. You may see air bubbles or hear a faint hissing sound.

- Increased friction or resistance when you try to inflate or deflate your tyre. This can make it hard to add air or check pressure.

- Loss of fluid or pressure, which leads to air loss and underinflated tyres.

These problems usually result from improper installation, worn or degraded packing materials, or exposure to extreme temperatures and harsh chemicals. You should always look for signs of faulty car tyre valve during your inspections.

How to Diagnose Valve Stem Issues

You can use simple methods to check for valve stem problems. Follow these steps:

- Apply soapy water to the tyre valve stem. Watch for bubbles, which signal leakage.

- Look for visible leaks around the valve stem or packing area.

- Notice if you have difficulty turning the valve or if it feels stiff.

- Check for pressure loss or fluid escaping from the valve.

- Inspect the valve stem core threads for corrosion. Use the tap end of a valve core tool to clean them if needed.

Tip: If you see bubbles or notice a drop in tyre pressure, you likely have a defective valve. Early detection is key to effective valve maintenance.

Steps to Fix Valve Stem Problems

You can resolve most valve stem issues with a few simple actions. Here is a step-by-step guide:

- Replace the packing or seal material if you find leakage or worn parts.

- Disassemble the valve if necessary. Clean the stem and packing area to remove debris.

- Lubricate the valve stem with a suitable valve lubricant. Lubrication reduces friction and helps the valve operate smoothly.

- Use a valve core tool to remove and install valve cores. This tool also cleans interior threads and restores cap threads.

- Screw in a new valve stem core carefully. Avoid over-tightening, which can damage the threads.

- Reinflate the tyre. Apply soapy water again to check for any remaining leakage.

- Reinstall the valve stem cap. This step keeps out dirt and helps prevent future leaks.

You should always perform preventive maintenance as part of your tyre care routine. Regular inspection and timely replacement of defective valves help you avoid unexpected air loss and tyre failure.

Table: Signs of Faulty Car Tyre Valve and Solutions

| Signs of Faulty Car Tyre Valve | Possible Cause | Solution |

|---|---|---|

| Air bubbles at valve stem | Seal failure or leakage | Replace seal, check for proper installation |

| Difficulty inflating tyre | Increased friction or corrosion | Clean threads, lubricate, replace core |

| Sudden air loss | Defective valve or packing | Replace valve stem, inspect for damage |

| Repeated pressure drops | Worn or degraded materials | Replace packing, perform regular maintenance |

Note: Consistent tyre valve maintenance, including cleaning, lubrication, and replacement, extends the life of your tyres and reduces the risk of leakage.

You can prevent most valve stem problems by following a regular maintenance schedule. Always check for signs of faulty car tyre valve, such as leaks, resistance, or pressure loss. Address issues quickly to keep your tyres in top condition.

Quick-Reference Valve Maintenance Checklist

You can use this valve maintenance checklist to keep your tires safe and your vehicle running smoothly. Regular maintenance helps you spot problems early and avoid unexpected issues on the road. Follow these steps to make sure each valve stays in top condition:

Inspect Each Valve Stem

Look for cracks, splits, or signs of aging. Check for leaks by applying soapy water to the valve. If you see bubbles, you have a leak.Check Valve Caps

Make sure every valve has a cap. The cap keeps out dirt and moisture. Replace missing or damaged caps right away.Clean the Valve Area

Wipe the valve with a clean cloth during every tire wash. Remove any dirt or debris that could cause leaks.Test Tire Pressure

Use a reliable gauge to check tire pressure at least once a month. If you notice a drop, inspect the valve for leaks or damage.Replace Worn or Damaged Valves

Change the valve if you see cracks, leaks, or if it feels brittle. Always replace valves when you install new tires.Lubricate Rubber Valves

Apply a small amount of silicone-based lubricant once a year. This keeps the rubber flexible and helps prevent cracking.Check High-Pressure and Specialty Valves

For vehicles with high-pressure tires or TPMS, use the correct valve type. Follow the manufacturer’s recommendations for replacement and maintenance.

Tip: Keep this valve maintenance checklist in your glove box or garage. Quick checks can save you from costly repairs and keep your ride safe.

| Task | How Often | What to Look For |

|---|---|---|

| Inspect valve stem | Monthly | Cracks, leaks, aging |

| Check valve cap | Every check | Missing or damaged caps |

| Clean valve area | Every tire wash | Dirt, debris |

| Test tire pressure | Monthly | Pressure drops, leaks |

| Replace valve | As needed | Cracks, leaks, new tires |

| Lubricate rubber valve | Yearly | Dryness, stiffness |

Stay consistent with your maintenance routine. This valve maintenance checklist helps you extend tire life and improve safety.

You play a key role in keeping your car tyre valve in top shape. Choose the right car tyre valve for your vehicle and follow proper valve maintenance. Regularly inspect each car tyre valve for cracks or leaks. Replace any car tyre valve that shows damage. Clean the area around the car tyre valve to prevent dirt from causing problems. Always check your tyre pressure and replace the car tyre valve when you get new tyres. If you feel unsure about your car tyre valve or tyre care, ask a trusted tyre shop for help.

Remember: Good care of your car tyre valve and tyre can prevent leaks, flats, and breakdowns.

FAQ

How often should you replace your valve stems?

You should replace valve stems every time you get new tires. If you see cracks, leaks, or signs of aging, change them right away. Regular replacement helps prevent air leaks and keeps your tires safe.

Can you use any valve stem on any tire?

No, you cannot use any valve stem on any tire. Always match the valve stem type and pressure rating to your tire and wheel. Using the wrong valve stem can cause leaks or even tire failure.

What happens if you drive with a damaged valve stem?

A damaged valve stem can cause slow air leaks or sudden tire deflation. You risk losing control of your vehicle. Always fix or replace a faulty valve stem before driving.

Do valve caps really matter?

Yes, valve caps protect the valve from dirt, moisture, and debris. They help prevent leaks and keep the valve working properly. Always replace missing or broken caps to extend valve life.

How do you check for valve stem leaks?

Apply soapy water to the valve stem and watch for bubbles. Bubbles mean air is escaping. If you see bubbles, replace the valve stem or core to stop the leak.