admin1

June 8, 2025

Adhesive Weights Reducing Environmental Impact in 2025

Adhesive weights are revolutionizing tire balancing by providing you with an efficient and environmentally friendly solution. Unlike traditional options, these weights eliminate harmful lead materials, making them safer for both you and the planet. Their adhesive design minimizes waste and simplifies recycling, helping you contribute to a cleaner environment. By choosing this innovative option, you support sustainable practices that enhance modern automotive standards. Fortune Auto Parts, a global leader in manufacturing, ensures these adhesive products meet the highest quality while promoting eco-conscious solutions for your tire needs.

Environmental Challenges of Traditional Wheel Weights

Lead Contamination and Toxicity

Traditional wheel weights, often made from lead, pose significant risks to your health and the environment. Lead is a toxic metal that can leach into soil and water, contaminating ecosystems and endangering wildlife. When improperly disposed of, these weights contribute to widespread lead pollution. Studies, such as the “Final Human Health State of the Science Report on Lead” (2013), highlight the severe health risks associated with lead exposure, including neurological damage and developmental issues in children.

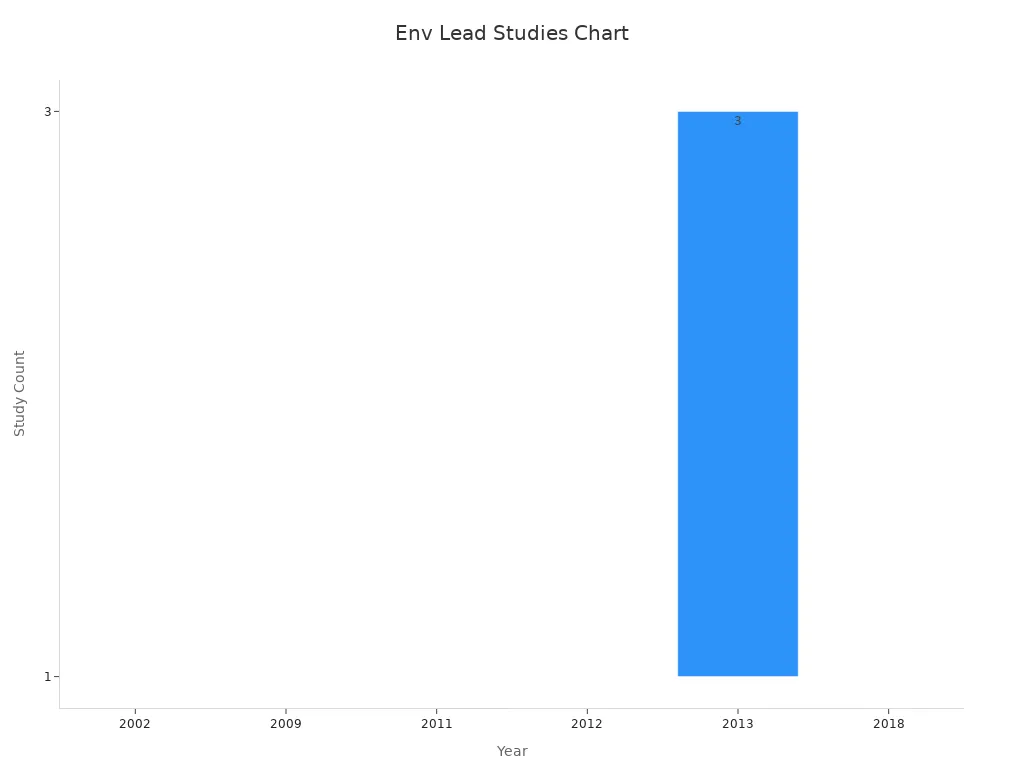

The table below summarizes key studies on the impact of lead contamination:

| Study/Report | Focus | Year |

|---|---|---|

| Toxicity of lead: a review with recent updates | Health effects of lead | 2012 |

| Final Human Health State of the Science Report on Lead | Overview of lead health risks | 2013 |

| Childhood lead poisoning: conservative estimates of the social and economic benefits of lead hazard control | Economic benefits of reducing lead exposure | 2009 |

Switching to non-lead alternatives, such as zinc wheel weights, can help you reduce these risks while supporting a cleaner environment.

Waste and Disposal Issues

Improper disposal of traditional wheel weights exacerbates waste management challenges. In many countries, recycling rates for tire-related materials remain alarmingly low. For instance:

- In Brazil, only 10% of the 300 tons of annual tire disposal is recycled, despite regulations mandating 100% recycling.

- In Turkey, 72.4 kilotons of end-of-life tires were collected, but only 33.4 kilotons were recycled.

The Environmental Protection Agency (EPA) reported that in 2018, 6.5 million tons of rubber tires were generated in the U.S., with a recycling rate of just 40%. Poor infrastructure and insufficient funding often hinder effective waste management. By adopting non-lead alternatives like zinc wheel weights, you can help reduce waste and promote sustainable practices.

Negative Effects on Ecosystems

Conventional wheel weights contribute to environmental degradation during production and disposal. Harmful substances like arsenic, cadmium, and chromium are released, damaging aquatic ecosystems. Arsenic ions, in particular, are highly toxic to aquatic life. Tire wear particles (TWPs) further exacerbate the problem, causing growth inhibition in aquatic organisms like Chironomus dilutes.

To mitigate these impacts, experts recommend regulating tire additives and promoting roadside plant growth. By choosing non-lead alternatives, you can play a role in protecting ecosystems and reducing environmental harm.

Eco-Friendly Advantages of Adhesive Weights

Lead-Free and Non-Toxic Materials

Adhesive weights offer a safer and more sustainable alternative to traditional lead-based wheel weights. By eliminating lead, these weights protect you and the environment from the harmful effects of toxic metals. Lead contamination has long been a concern due to its severe health risks and its ability to pollute soil and water. Adhesive weights, on the other hand, are crafted from eco-friendly materials like zinc, steel, and polymer composites.

| Material | Eco-Friendly Attributes |

|---|---|

| Steel | Recyclable, non-toxic, cost-effective, durable |

| Zinc | Less toxic than lead, favorable density, malleability, but requires monitoring |

| Polymer Composites | Derived from recycled plastics or natural fibers, lower manufacturing carbon footprint |

| Tungsten | High density, used in specialized applications, environmental footprint considerations |

| Biodegradable Adhesives | Plant-based or rapid-degrading options align with green priorities |

| Process Innovations | Precision engineering reduces waste, modular designs promote recycling, eco-friendly packaging reduces plastic use. |

These materials not only reduce toxicity but also align with global sustainability goals. For example, polymer composites derived from recycled plastics or natural fibers significantly lower the carbon footprint during manufacturing. By choosing adhesive wheel weights, you actively contribute to a cleaner, healthier planet.

Enhanced Recyclability and Reduced Waste

Adhesive weights excel in recyclability, making them a standout choice for eco-conscious consumers like you. Unlike traditional wheel weights, which often end up in landfills, adhesive weights are designed with recycling in mind. Specialized adhesives enhance the recyclability of packaging materials, ensuring that fewer resources are wasted.

- Recyclable paper label materials are now available for fiber packaging and rigid packaging streams like HDPE, PP, and PET.

- Lightweighting practices have reduced the use of virgin materials, cutting plastic packaging weight by up to 33% in PET bottles over the past decade.

These innovations demonstrate how adhesive weights minimize waste and promote sustainable practices. By adopting these advanced solutions, you help reduce the environmental burden caused by traditional tire balancing methods.

Lightweight Design for Improved Efficiency

The lightweight design of adhesive weights offers significant benefits for both your vehicle and the environment. By reducing the overall weight of your car, these weights improve fuel efficiency and lower emissions. Research shows that a 10% reduction in vehicle weight can lead to a 6-8% improvement in fuel economy.

Adhesive weights utilize materials like magnesium, aluminum alloys, and carbon fiber to achieve this lightweight advantage. These materials can reduce vehicle weight by up to 50%, making them ideal for modern automotive applications. Pressure-sensitive adhesives (PSAs) also play a crucial role by enabling the bonding of lightweight materials such as aluminum and fiber-reinforced composites. This innovation supports sustainable vehicle construction while enhancing energy efficiency.

The U.S. Department of Energy continues to research lightweight materials to improve vehicle components. These advancements not only enhance fuel economy but also contribute to better driving performance and reduced greenhouse gas emissions. With adhesive weights, you gain a clean hidden look for your wheels while supporting a greener future.

Stick-On Wheel Weights and Modern Vehicle Compatibility

Aerodynamic Benefits

Stick-on wheel weights are designed to enhance your vehicle’s aerodynamics, offering a sleek and efficient solution for tire balancing. Unlike traditional clip-on weights, which protrude and disrupt airflow, these adhesive weights sit flush against the wheel surface. This streamlined design minimizes drag, allowing your vehicle to move more smoothly through the air.

Why does this matter to you? Reduced drag translates to better handling and improved performance on the road. Whether you’re driving at highway speeds or navigating city streets, the aerodynamic advantage of stick-on wheel weights ensures a quieter, more stable ride. Additionally, the hidden placement of these weights preserves the aesthetic appeal of your wheels, giving them a clean and polished look.

By choosing stick-on wheel weights, you not only achieve optimal tire balance but also enjoy the benefits of enhanced aerodynamics. This innovation supports both your driving experience and the environment by reducing energy loss caused by air resistance.

Contribution to Fuel Efficiency and Emissions Reduction

Stick-on wheel weights play a crucial role in improving your vehicle’s fuel efficiency. Their lightweight design reduces the overall weight of your tires, which directly impacts fuel consumption. Studies show that even a small reduction in vehicle weight can lead to significant savings at the pump. For example, a 10% decrease in weight can improve fuel economy by 6-8%.

Precise weight distribution, achieved through these adhesive weights, ensures that your tires rotate evenly. This reduces rolling resistance, which is a major factor in fuel consumption. Lower rolling resistance means your engine doesn’t have to work as hard, resulting in fewer emissions and a smaller carbon footprint.

If you’re looking to make your vehicle more eco-friendly, stick-on wheel weights are an excellent choice. They align with global efforts to reduce greenhouse gas emissions while helping you save money on fuel. By adopting this modern solution, you contribute to a cleaner planet without compromising on performance.

Durability and Safety in Various Conditions

Stick-on wheel weights are engineered to withstand the toughest driving conditions, ensuring your safety and peace of mind. These weights undergo rigorous testing to meet industry standards like SAE J246 and DIN 7745, which guarantee accuracy and material quality. High adhesive strength ensures that the weights remain securely attached, even during extreme temperature changes or high-speed driving.

Here’s what makes them reliable:

- Hardness values ranging from 6 to 11.5 BHN provide resistance to wear and tear, comparable to traditional clip-on weights.

- High-temperature resistance tests confirm that the adhesive won’t degrade in hot climates.

- Thermal shock resistance tests prove their ability to endure sudden temperature shifts, such as driving through snow and then into a heated garage.

These features make stick-on wheel weights a dependable choice for all types of vehicles and terrains. Whether you’re navigating icy roads or cruising under the summer sun, you can trust these weights to maintain optimal tire balance and ensure your safety. Their durability also means fewer replacements, saving you time and money in the long run.

By investing in stick-on wheel weights, you gain a solution that combines safety, durability, and improved performance. This innovation not only enhances your driving experience but also supports sustainable automotive practices.

Innovations and Future Trends in Adhesive Weights

Advanced Materials and Manufacturing Techniques

Adhesive weights are evolving rapidly, thanks to cutting-edge advancements in materials and manufacturing. You benefit from innovations like hybrid adhesives that combine different chemistries for superior performance. These adhesives adapt to external stimuli, self-heal, and improve durability, making them ideal for high-tech applications. Industry 4.0 integration is transforming production processes with automated dispensing systems, ensuring higher quality and productivity.

Environmental regulations are driving the shift toward lead-free and zinc-based weights, offering you safer and more sustainable options. Lightweight, multi-material designs are becoming the norm, especially for electric vehicles. These designs reduce weight while maintaining strength, enhancing your vehicle’s efficiency. The adhesives industry is also focusing on PFAS-free formulations to minimize toxic emissions and waste, aligning with global sustainability goals.

Digitalization and automation in manufacturing further enhance productivity and quality control. By choosing products made with advanced adhesive technology, you support innovation while enjoying better performance and eco-friendly benefits.

Integration with Smart Vehicle Systems

Adhesive weights are now compatible with smart vehicle systems, offering you a seamless integration with modern automotive technology. These weights work with sensors and onboard diagnostics to monitor tire balance in real time. This ensures optimal performance and safety, whether you’re driving on highways or rugged terrains.

Smart adhesives are also making waves in the automotive industry. They adapt to external conditions, such as temperature changes, and maintain their strength and flexibility. This innovation reduces the need for frequent replacements, saving you time and money. As electric and autonomous vehicles become more prevalent, adhesive weights tailored for these applications will enhance efficiency and reliability.

By adopting adhesive weights designed for smart systems, you gain access to cutting-edge technology that improves your driving experience while supporting sustainable practices.

Role in Achieving Sustainability Goals by 2025

Adhesive weights are playing a pivotal role in helping you and the automotive industry meet sustainability goals by 2025. Their lightweight design reduces fuel consumption and emissions, contributing to a cleaner environment. Innovations in formulation technologies, such as bio-based adhesives, align with environmental standards and reduce the carbon footprint of manufacturing.

The demand for greener products is pushing industries to prioritize performance and sustainability. Adhesive weights crafted from recyclable materials like zinc and polymer composites ensure minimal waste and maximum efficiency. These advancements support global efforts to reduce greenhouse gas emissions and promote eco-friendly practices.

By choosing adhesive weights, you actively participate in achieving sustainability targets. This decision not only benefits the planet but also ensures a better future for generations to come.

Adhesive weights are transforming the way you balance tires, offering a cleaner and safer alternative to traditional methods. Their lead-free materials and recyclable design make them an eco-friendly choice that aligns with modern sustainability goals. By switching to adhesive weights, you actively reduce waste and support a greener future.

🌍 Take action today! Choose adhesive weights to drive change and contribute to a cleaner planet. By 2025, your decision will help shape a more sustainable automotive industry.

Make the switch now and be part of the solution!

FAQ

What makes adhesive weights better than traditional wheel weights?

Adhesive weights eliminate lead, making them safer for you and the environment. Their lightweight design improves fuel efficiency, while their sleek appearance enhances your vehicle’s aerodynamics. Plus, they’re recyclable, reducing waste and supporting sustainable practices. Choose adhesive weights for a cleaner, smarter solution.

Are adhesive weights durable in extreme weather conditions?

Yes, adhesive weights are engineered to withstand temperature extremes. Rigorous testing ensures they stay securely attached during heatwaves, snowstorms, or sudden temperature shifts. Their high adhesive strength guarantees reliable performance, keeping your tires balanced and your ride safe in any climate.

Can adhesive weights improve my vehicle’s fuel efficiency?

Absolutely! Adhesive weights reduce your vehicle’s overall weight, lowering rolling resistance and improving fuel economy by up to 8%. This means fewer emissions and more savings at the pump. By switching to adhesive weights, you drive smarter and greener.

Are adhesive weights compatible with electric and autonomous vehicles?

Yes, adhesive weights are designed for modern vehicles, including electric and autonomous models. Their lightweight materials and aerodynamic benefits align perfectly with advanced automotive technologies, ensuring optimal performance and efficiency for your cutting-edge ride.

How do adhesive weights contribute to sustainability goals?

Adhesive weights use recyclable materials like zinc and polymer composites, reducing waste and pollution. Their lightweight design cuts emissions, while innovations like bio-based adhesives lower manufacturing carbon footprints. By choosing adhesive weights, you actively support global sustainability efforts for a greener future.